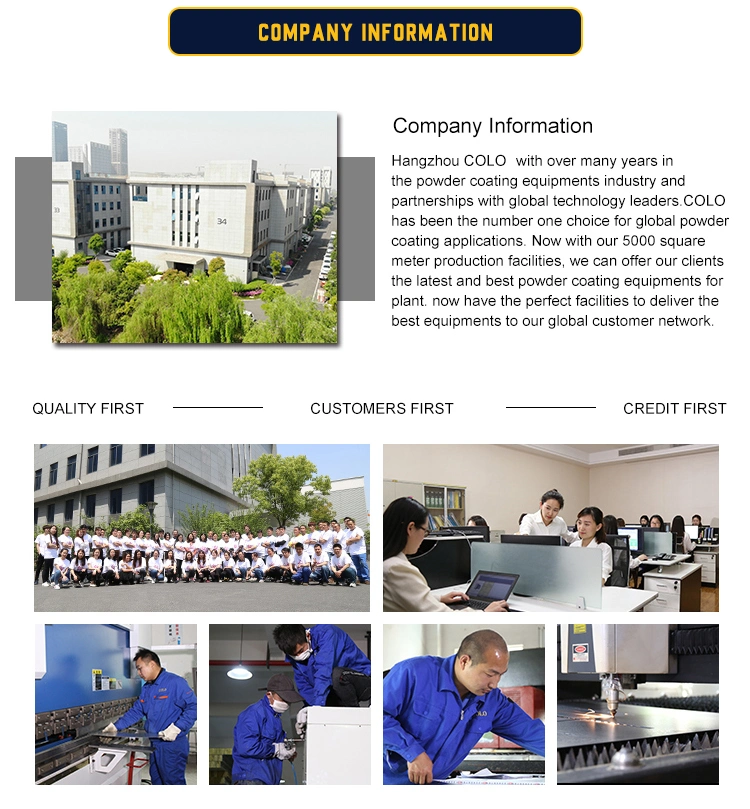

Colo Compact Open Face Batch Filter Powder Coating Spray Paint Cabin Booth for Wheel Rim

Basic Info.

| Model NO. | COLO-S-1517 |

| Condition | Used |

| Application | Metal Powder Coating Collection |

| Controller Language | English, Spanish, as Required |

| Operator Dimensions | W1500*D1000*H1700mm |

| Filter Material | Polyester |

| Powder Coating Oven | Option |

| Light | 2 Sets |

| Coating Spray Gun | Option |

| Drawing | Avaiable |

| Filters Hang Type | Easy for Change |

| Filter Cleaning System | Pneumatic |

| Filter Size | 325*900mm |

| Filters Count | 3 PCS |

| Exhaust Fan | 2.2kw |

| Air Flow | 4000m3/H |

| Voltage | 220-600V 3phase |

| Transport Package | Wooden Carton |

| Specification | 7CBM |

| Trademark | HICOLO |

| Origin | China |

| HS Code | 8424899990 |

| Production Capacity | 200PCS Per Month |

Product Description

COLO Powder Coating Spray Paint Cabin for Wheel RimAn economical solution for basic powder coating operations requiring reclaim capability in continuous production situations.COLO-S-1517 Powder coating booth provides a bright and clean environment for spraying process. Space-saving manual powder booth features easy and economical for powder application of small and medium-sized workpieces.

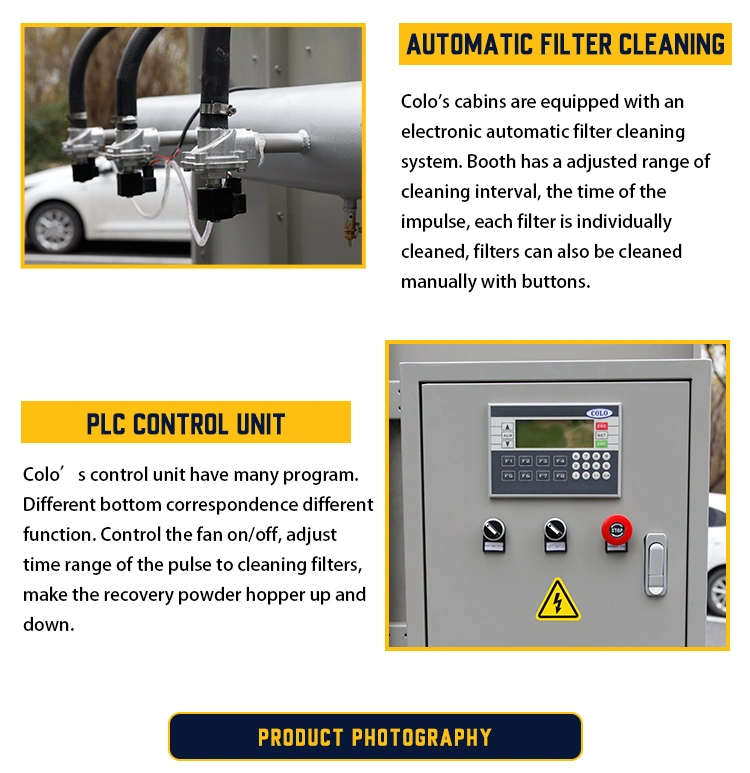

An integrated and innovative powder collection module is designed for effectively capturing oversprayed powder. The pneumatic controlled pulse-jetting system regularly cleans filter to prevents powder accumulation and extend filter life.

- All components with premium quality and performance to get an ideal cleaning and powder recovery.Manual Powder Coating Booth for wheel rim Feature:

1. A high-performance fan efficiently circulate air with low noise and less energy.

2. 0.1 Micron high-precision filters ensures only particle-free air discharged to workshop and increase powder recovery rate.

3. Powder-coated steel constructed booth is corrosion resistant for longer service life.

4. A removable powder hopper at booth bottom simplifies the utilization of recovery powders

6. A user-friendly PLC panel integrates all functions, such turning on / off fans, setting pulse-jetting time and interval, light on/off, emergency stop etc.

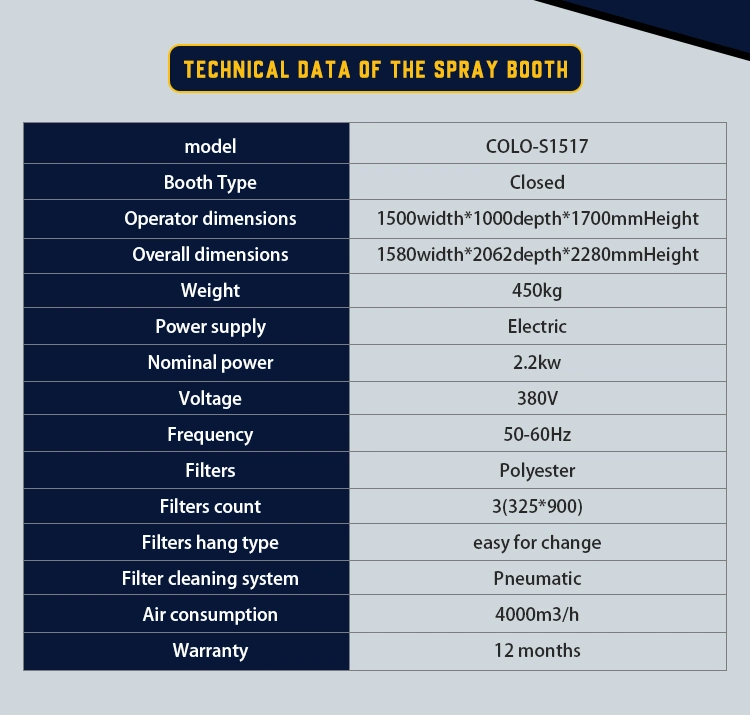

Manual Powder Coating Booth Specifications:

| Model | COLO-S-1517 |

| Operating Dimensions | Width1500*Depth1000*Heght1700mm |

| Overall dimensions | Width1600*Depth2000*Heght2250mm |

| Weight | 480kg |

| Power Supply | 220V/380V, 3Phase, 50-60HZ |

| Fan Power | 2.2kw |

| Filter Count | 3 pcs, Quick-release Type |

| Filter Material | Polyester |

| Filter Cleaning | Pneumatic |

| Air Consumption | 4000m^3/h |

How does powder coating booth work?

The powder spray booth fan draws air through filters that creates a negative pressure in the chamber, thus oversprayed powders in the air flow will gather in the filters while an automatic pulse-jetting device cleans the filter by interval, through which powders drop into a recovery hopper beneath the booth.